The manual ingredient animal feed processing unit is a semi-automatic feed production equipment that mainly relies on manual operation to complete the proportioning and feeding of raw materials. It is suitable for small and medium-sized feed processing plants or scenarios that require high production flexibility. This equipment has low cost, simple operation, and is suitable for producing various formulations of feed.

★Main components★

1. Raw material storage system:

-Including multiple raw material warehouses or storage hoppers, used to store different feed materials (such as corn, soybean meal, wheat bran, etc.).

-Each raw material warehouse is usually equipped with manual or semi-automatic discharge devices.

2. Artificial ingredient area:

-Operators manually weigh various raw materials according to the formula requirements.

-Use weighing equipment such as platform scales and electronic scales to ensure accurate proportioning.

3. Conveyor System:

-Using screw conveyors, belt conveyors, or manual feeding methods, the weighed raw materials are transported to the mixer.

4. Mixing System:

-Mixing the prepared raw materials evenly, common equipment includes horizontal mixers, vertical mixers, etc.

-The mixing time can be adjusted according to the formula requirements.

5. Crushing system (optional):

-Used to grind raw materials to the desired particle size, usually equipped with a hammer crusher.

6. Granulation system (optional):

-Crush the mixed feed into granules to improve its palatability and storage performance.

7. Packaging System:

-Bagging finished feed is usually done using semi-automatic packaging machines or manual packaging.

★Characteristics★

1. High flexibility:

-Artificial ingredients can adjust the formula as needed, suitable for small batch and multi variety production needs.

2. Low cost:

-Less equipment investment, suitable for small and medium-sized feed processing plants or breeding farms.

3. Easy to operate:

-The technical requirements for operators are relatively low and easy to learn.

4. Strong adaptability:

-It can process various raw materials and is suitable for the production of different types of animal feed.

5. Semi automated:

-The processes of mixing, crushing, and granulation can be semi automated, reducing manual labor intensity.

★Application Fields★

-Small and medium-sized feed factories: used for producing animal and aquatic feed.

-Farm: Used for self preparation and self use of feed to reduce costs.

-Experimental Feed Production: Used for small-scale, multi formula experimental feed production.

The artificial ingredient animal feed processing unit is an economical and practical choice, especially suitable for small and medium-sized feed production enterprises or breeding farms, which can reduce production costs while ensuring feed quality.

-

1-2TPH Livestock and Poultry Feed Production Line

1-2TPH Livestock and Poultry Feed Production Line 1-2TPH Livestock and Poultry Feed Production Line

1-2TPH Livestock and Poultry Feed Production Line 1-2TPH Ruminant Feed Production Line

1-2TPH Ruminant Feed Production Line 1-2TPH Ruminant Feed Production Line

1-2TPH Ruminant Feed Production Line 2-4TPH Livestock and Poultry Feed Production Line

2-4TPH Livestock and Poultry Feed Production Line 2-4TPH Livestock and Poultry Feed Production Line

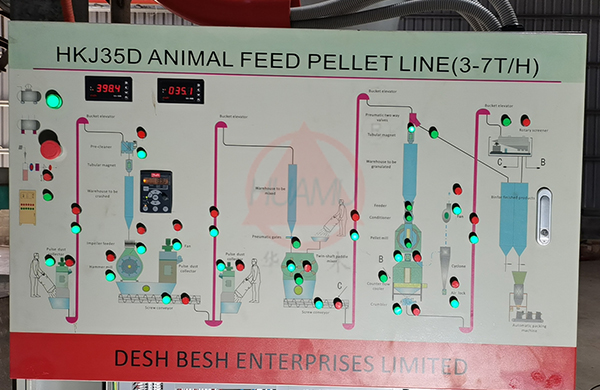

2-4TPH Livestock and Poultry Feed Production Line 2-7TPH Livestock and Poultry Feed Production Line

2-7TPH Livestock and Poultry Feed Production Line 2-7TPH Livestock and Poultry Feed Production Line

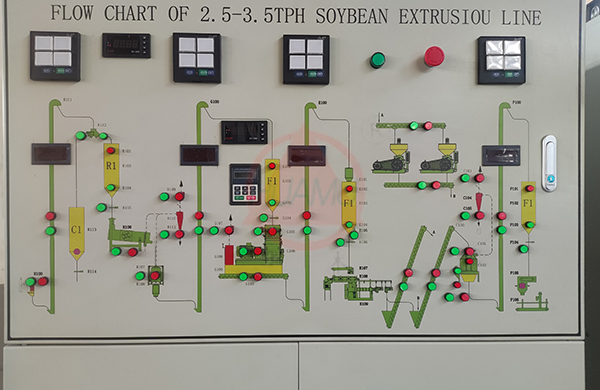

2-7TPH Livestock and Poultry Feed Production Line 2-3TPH feed raw material puffing production line

2-3TPH feed raw material puffing production line 2-3TPH feed raw material puffing production line

2-3TPH feed raw material puffing production line 2-3TPH feed raw material puffing production line

2-3TPH feed raw material puffing production line 2-3TPH feed raw material puffing production line

2-3TPH feed raw material puffing production line 1-2TPH Special Aquatic Puffed Feed Production Line

1-2TPH Special Aquatic Puffed Feed Production Line 1-2TPH Special Aquatic Puffed Feed Production Line

1-2TPH Special Aquatic Puffed Feed Production Line

地址:无锡市锡山区锡北镇

地址:无锡市锡山区锡北镇 24小时销售热线:18706199000

24小时销售热线:18706199000 传真:0510-83795318

传真:0510-83795318 邮箱:huamu@china-huamu.com

邮箱:huamu@china-huamu.com