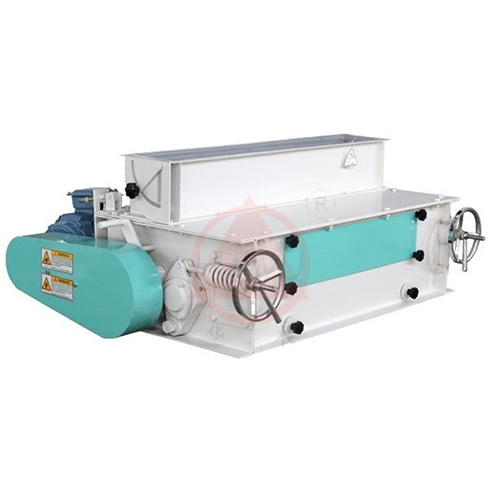

★ is a specialized equipment for crushing large particles into small particles, with a compact structure and uniform crushing. Particle adjustment is convenient and fast, and there is no need for a bypass device to bypass materials when crushing.

★ The tying roller operates at a differential speed, and the granular material is subjected to compression, shearing, and tearing between the two rollers, thereby achieving the desired crushing effect.

★ Smooth transmission, low noise, reliable operation, and easy operation.

★ Suitable for crushing pellet feed in feed mills, as well as crushing soybeans, corn, and soft minerals.

Main Technical and Performance Index Parameter Table

Model

SSLG15×60

SSLG15×80

SSLG15×100

SSLG15×150

SSLG15×150

Capacity(t/h)

1-2

2-4

3-6

5-10

5-12

Power(kw)

3.0

4.0

5.5

7.5

11

Main Technical and Performance Index Parameter Table

Model

SSLG20×80×3

SSLG20×100×3

SSLG20×140×3

SSLG20×170×3

Capacity(t/h)

3-6

5-10

8-16

15-20

Power(kw)

5.5+1.1

7.5+1.5

11+1.5

18.5+1.5

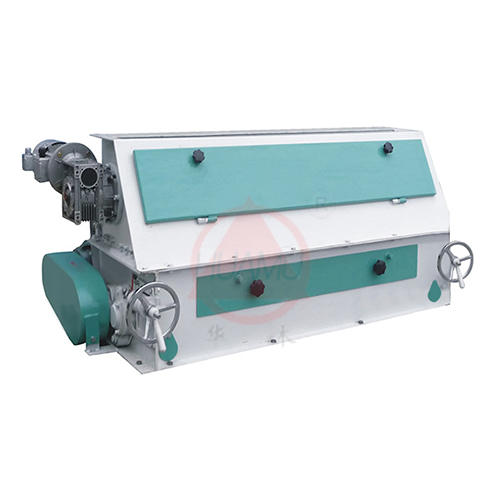

Egg chicken feed crusher:

The machine adopts the principle of roller differential speed to squeeze and shear the incoming material, breaking down large particles into irregular small particles;

The machine adopts a pneumatic flap door and an impeller variable frequency feeder to adjust the feeding speed and effectively improve the crushing output.

The machine is equipped with four sets of instruments for adjusting the gap between the rollers, which intuitively display the size of the roller gap and facilitate operation.

The roll protection device automatically avoids hard foreign objects when the roll encounters them, protecting the roll from damage. When there is no need to break, there is a bypass device to discharge the material;

The rolling mill is made of alloy cast iron material through double-layer cold hard centrifugal casting, with extremely strong wear resistance and long service life;

This machine combines the strengths of various crushing machines at home and abroad, and is an efficient, low-noise, and durable device;

Mainly suitable for crushing pellet feed in feed factories, it can also be used for crushing materials such as soybeans, corn, and soft minerals.

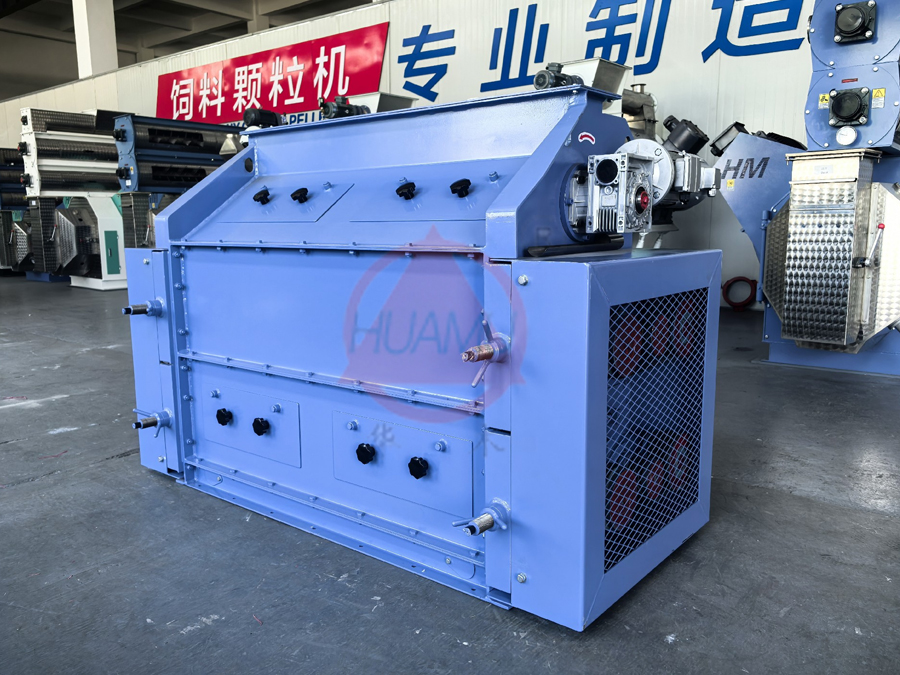

Dual axis blade mixer:

Dual axis blade design, special arrangement structure, high mixing uniformity, short mixing cycle; Mixing time 1-3 minutes, coefficient of variation CV<5%;

Adopting a full length open door discharge structure, the discharge is rapid, ensuring low residue and preventing cross contamination;

◆ Airbag sealing strip with good sealing performance; Set up return air ducts to ensure no dust leakage and fully meet environmental protection requirements.

Materials with significant differences in physical properties such as specific gravity, particle size, and shape are less prone to segregation during mixing;

Equipped with a liquid addition system, it can add various liquids (water, oil, sugar, etc.);

◆ Adopting a hard tooth surface reducer and rotor direct transmission; Smooth and reliable transmission, long service life, and low maintenance costs;

The container size is limited, and the mixer is designed with a detachable shell for easy transportation.

Equipped with safety interlock devices to protect personal safety;

Carbon steel or stainless steel materials can be selected according to different purposes;

◆ Suitable for industries such as feed, additives, chemicals, pharmaceuticals, pesticides, dyes, and food.

-

地址:无锡市锡山区锡北镇

地址:无锡市锡山区锡北镇 24小时销售热线:18706199000

24小时销售热线:18706199000 传真:0510-83795318

传真:0510-83795318 邮箱:huamu@china-huamu.com

邮箱:huamu@china-huamu.com